A Fully Automated Assembly Line

Product Features

No. | Customer Picture | Component | Specification | Drawing received | Sample received |

1 |

| Barrel | No | No | |

2 |

| Cannula | No | No | |

3 |

| Front Cap | No | No | |

4 |

| Gasket | No | No | |

5 |

| Plug | No | No | |

6 |

| Back Cap | No | No |

1 |

|

| 360Parts/Min |

| |||

| |||

| |||

| |||

|

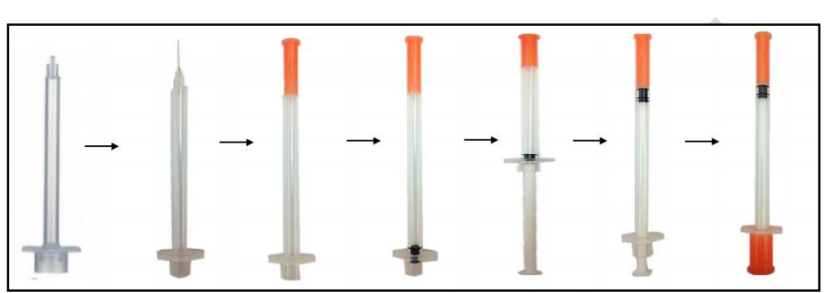

1.3 Assembly and process steps

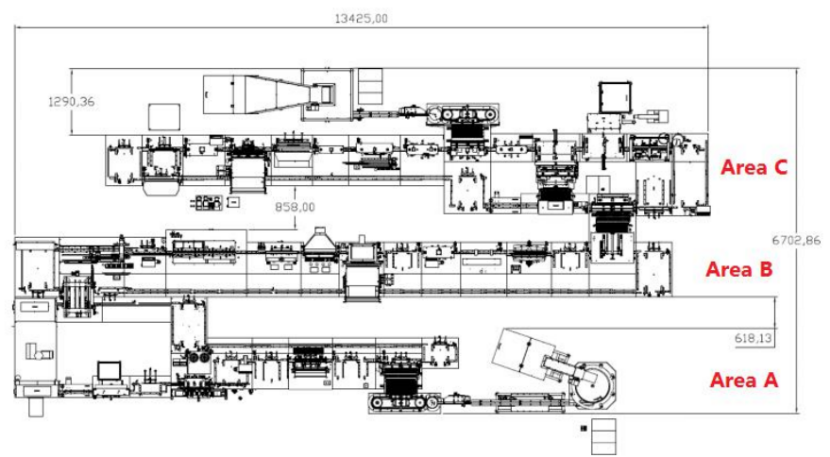

1.4 Machine layout

1.5 Machine process stations

No. | Stations | Comments |

A01 | Feeding the barrel | By centrifugal and Elevator |

A02 | Plasma treatment | |

A03 | Checking the existence of the barrel by fiber and Rejecting the Jig without full barrel to the manual feeding area | |

A04 | Feeding the cannula | |

A05 | Checking the existence of the cannula by fiber and Rejecting the Jig without full cannula to the manual feeding area | |

A06 | Gluing | UVglue |

A06 | Procuring | |

A07 | Enter oven | |

A08 | Out of oven | |

A09 | Change jig of Area A to jig of Area B | |

A10 | Jig of Area Are flow | |

B01 | Change jig of Area B from jig of Area A | |

B02 | CCD check burrs,the Invert and Verticality of the cannula | |

B03 | Siliconizationa and blow for the cannula | |

B04 | Blockage test for the cannula | |

B05 | Rejecting the NG parts | |

B06 | Feeding the front cap in place | |

B07 | Checking the existence of the front cap by fiber and Rejecting the Jig without full front cap to the manual feeding area | |

B08 | Hotting one point of the front cap | |

B09 | Change jig of Area B to jig of Area C | |

B10 | Jig of Area B reflow | |

C01 | Change jig of Area B from jig of Area A | |

C02 | Barrel siliconization | |

C03 | Feeding the gasket | |

C04 | Feeding and Assembling the plug | |

C05 | Lifting the plug | |

C06 | Checking the existence of the gasket | |

C07 | Pressing the plug | |

C08 | Rejecting the NG parts | |

C09 | Feeding and Assembling the back cap | |

C10 | Pressing the back cap | |

C11 | Checking the existence of the back cap | |

C12 | Rejecting the Jig without full back cap to the manual feeding area | |

C13 | Good parts unloading |

1.6 Technical data

Item | Parameter | Item | Parameter |

Power | 15KW | Voltage | 380V-50Hz |

Pressure | 0.5-0.7MPa | Nominal Output | 22,000PCS/Hour |

Machine size(L x W x H) | 13.5 x 6.7 x 2.1m | Weight | 5,000KG |

Reject ratio | ≤2% | Number of operators | 3-4 |

1.7 Hardware

Item | Brand | Item | Brand |

PLC System | Keyence | Touch Screen | PRO-face |

Servo System | Panasonic | Vision System and devices | Keyence |

Photo Electric Sensors | Leuze | Pneumatic Components | SMC |

Main Specification

1.5 Machine process stations

No. | Stations | Comments |

A01 | Feeding the barrel | By centrifugal and Elevator |

A02 | Plasma treatment | |

A03 | Checking the existence of the barrel by fiber and Rejecting the Jig without full barrel to the manual feeding area | |

A04 | Feeding the cannula | |

A05 | Checking the existence of the cannula by fiber and Rejecting the Jig without full cannula to the manual feeding area | |

A06 | Gluing | UVglue |

A06 | Procuring | |

A07 | Enter oven | |

A08 | Out of oven | |

A09 | Change jig of Area A to jig of Area B | |

A10 | Jig of Area Are flow | |

B01 | Change jig of Area B from jig of Area A | |

B02 | CCD check burrs,the Invert and Verticality of the cannula | |

B03 | Siliconizationa and blow for the cannula | |

B04 | Blockage test for the cannula | |

B05 | Rejecting the NG parts | |

B06 | Feeding the front cap in place | |

B07 | Checking the existence of the front cap by fiber and Rejecting the Jig without full front cap to the manual feeding area | |

B08 | Hotting one point of the front cap | |

B09 | Change jig of Area B to jig of Area C | |

B10 | Jig of Area B reflow | |

C01 | Change jig of Area B from jig of Area A | |

C02 | Barrel siliconization | |

C03 | Feeding the gasket | |

C04 | Feeding and Assembling the plug | |

C05 | Lifting the plug | |

C06 | Checking the existence of the gasket | |

C07 | Pressing the plug | |

C08 | Rejecting the NG parts | |

C09 | Feeding and Assembling the back cap | |

C10 | Pressing the back cap | |

C11 | Checking the existence of the back cap | |

C12 | Rejecting the Jig without full back cap to the manual feeding area | |

C13 | Good parts unloading |

1.6 Technical data

Item | Parameter | Item | Parameter |

Power | 15KW | Voltage | 380V-50Hz |

Pressure | 0.5-0.7MPa | Nominal Output | 22,000PCS/Hour |

Machine size(L x W x H) | 13.5 x 6.7 x 2.1m | Weight | 5,000KG |

Reject ratio | ≤2% | Number of operators | 3-4 |

1.7 Hardware

Item | Brand | Item | Brand |

PLC System | Keyence | Touch Screen | PRO-face |

Servo System | Panasonic | Vision System and devices | Keyence |

Photo Electric Sensors | Leuze | Pneumatic Components | SMC |

+86 139 1863 8349

+86 21 5839 9546

+86 21 5839 9546

HQ Add.: Room 1601 Haibo Bldg.| No.101 Nanmatou Road | Pudong New District Shanghai 200125 China

Manufacturing Facility Add.: No.26 Huashan Middle Road, Changzhou, Jiangsu Province 213022 China

Navigation