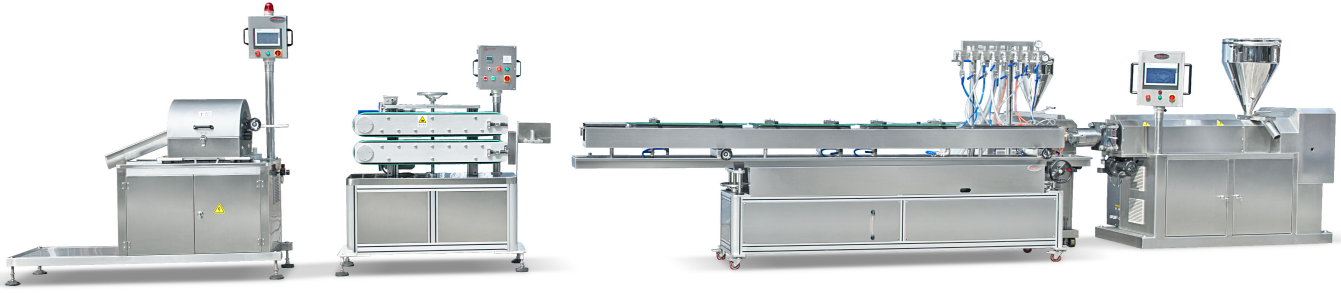

Automatic Medical Tubing Extrusion Line

The production line is designed with a unique double-knife online cutting mode (that is, cutting two products at the same time at a time), which doubles the efficiency of the conventional production mode.

With more than ten years of development, VITAIMED has established good cooperation relationship with global medical partners, providing high-quality medical products and services for global medical partners.

Product Features

Equipment Parameters

Overview

1. Raw Material: PETG

2. Output: 32PCS/MIN (Burette Tube)

Operation Conditions

1. Voltage: 380V/3P/50HZ(Unless otherwise specified)

2. Center height: 1000mm

3. Total power supply: 65KW

4. Power consumption during normal production: ≈32KW

5. Recommended water temperature: 8℃~12℃

6. Compressed air:≈0.6 MPA (<10M³/H)

7. Footprint: 9M (L) X 1.5 M(W) X 2.3M (H)

8. Water, electricity, air connection location refer to Machine Layout.

Main Specification

Co-extrusion Tooling

1. High precision Co-extrusion Head: 1set

2. High precision Co-extrusion Die: 1set

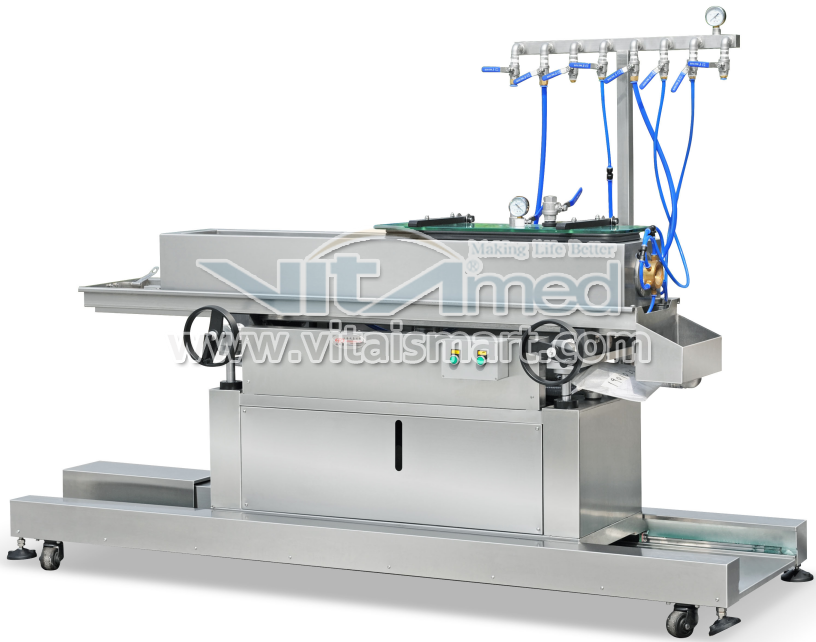

2M Cooling Trough

1. Length: 2M

2. Body: 2MM thick 304 stainless steel bending welding forming

3. Water-ring vacuum pump, Power:2.2KW

4. Stainless steel water reservior

5. Nylon guiding wheel, adjustable support arm

6. Back and forth travel: ±200mm, mechanical gear rrive, manual operation

7. Up and down travel: ±50mm,manual operation

8. Left and right travel: ±50mm,manual operation

9. Frame: Aluminum alloy frame with SUS304 seal-plate

10. Water level controller and water flow bidirectional controller fitted in the water trough

Belt Puller

1. High precision rolling ball guideway

2. Threaded rod to develop or restore the upper and lower belt opening as well as the puller operational center height

3. High-efficiency and stability foamed ribbed belt

4. Low inertial ribbed belt pulley

5. High precision worm-gear reducer

6. Japan Yaskawa servo driver

7. Guangdong Jiangsheng motor

8. Driving Power: 2 X 1.1KW

Dual-blade Cutter

1. Low-inertia aluminum alloy rotary blade arm

2. Fitted with special cutter bushing makes kerf smooth without thorn

3. Japan Yaskawa servo motor

4. Japan Yaskawa servo controller

5. Driving power:400W

6. Siemens HMI

7. Automatic counting function

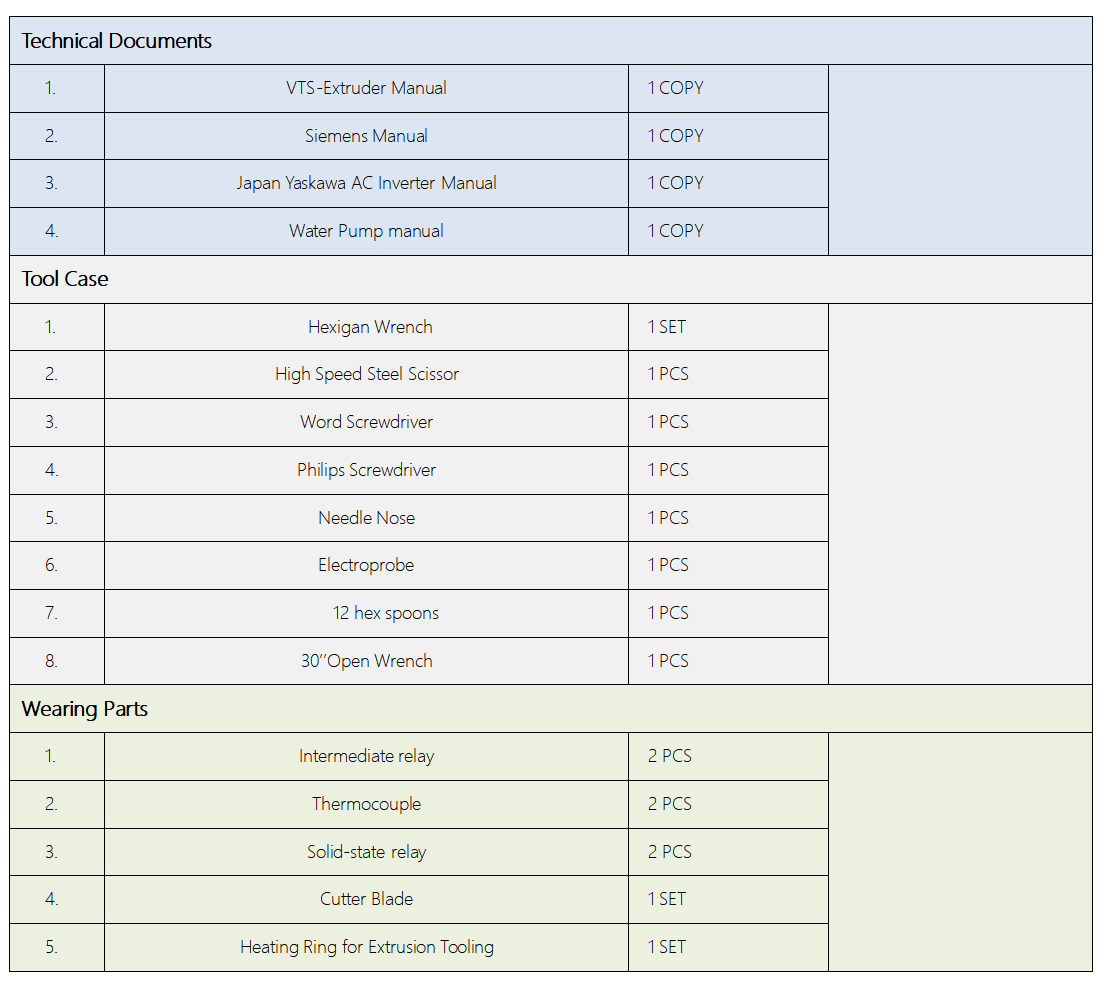

Spare Part List

+86 139 1863 8349

+86 21 5839 9546

+86 21 5839 9546

HQ Add.: Room 1601 Haibo Bldg.| No.101 Nanmatou Road | Pudong New District Shanghai 200125 China

Manufacturing Facility Add.: No.26 Huashan Middle Road, Changzhou, Jiangsu Province 213022 China

Navigation